V series plate heat exchangers compliant with the NB/T47004.1 - 2017 standard

Product solutions for detachable plate heat exchangers

Plate heat exchangers belong to the category of indirect heat exchangers. They feature high heat transfer efficiency, low resistance loss, compact structure, sensitive temperature control, large operating flexibility, convenient assembly and disassembly, and long service life. They are currently the most advanced high - efficiency energy - saving heat exchange equipment. Plate heat exchangers are mainly used in heating, cooling, evaporation, condensation, sterilization, and thermal recovery scenarios.

The plate heat exchanger products designed and manufactured by ViEX can handle a wide range of materials, from ordinary civil and industrial water to high - viscosity fluids; from food fluids and pharmaceutical fluids with high hygiene requirements to highly corrosive chemical media; from very clean liquid materials to liquids containing a small amount of fibers. At present, they have been widely applied in industries such as petroleum, chemical engineering, metallurgy, mining, electric power, nuclear power, central heating, shipping, pharmaceuticals, food, chemical fiber, electronics, automotive, light textiles, and papermaking.

ViEX detachable plate heat exchangers mainly include: plate heat exchangers dedicated to central heating, plate heat exchangers dedicated to nuclear power, plate heat exchangers with shallow and dense corrugations dedicated to the air - conditioning and refrigeration industry, plate heat exchangers dedicated to the beverage industry, plate heat exchangers dedicated to metallurgy, plate heat exchangers dedicated to petrochemicals, and detachable wide - channel plate heat exchangers.

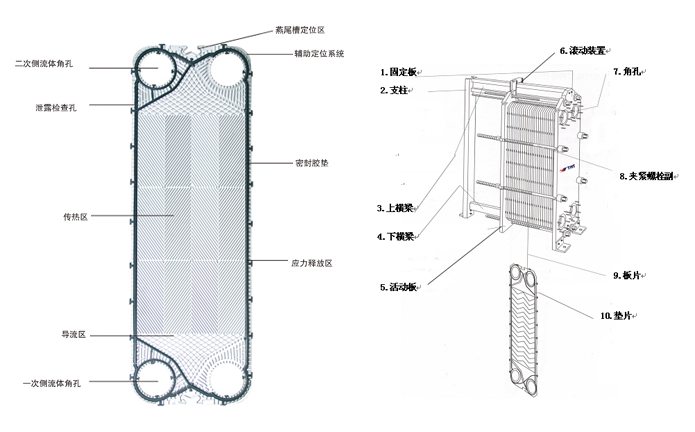

Structural principle

NO. | Part Name | Part Function |

1 | Fixed Plate | It does not come into direct contact with the fluid. After being tightened by the clamping bolt pair, it presses the plates and gaskets to ensure sealing. |

2 | Bracket | Supports the weight of the heat exchanger and integrates the entire heat exchanger. |

3、4 | Upper and Lower Crossbeams | Bears the weight of the heat exchanger and ensures the installation dimensions, allowing the plates to slide between them. The crossbeams are usually longer than the clamped plate pack to ensure that the plates can be assembled, inspected, and washed after loosening the clamping bolts. |

5 | Movable Plate | Used in pairs with the fixed plate, it slides freely on the crossbeam for easy disassembly and assembly of the heat exchanger. |

6 | Rolling Device | Enables the movable plate or intermediate partition to slide freely on the crossbeam. |

7 | Corner Hole | The distribution pipe and collection pipe for the medium to enter the heat exchange plates. |

8 | Clamping Bolt Pair | Compresses the plate pack to ensure the overall sealing of the heat exchanger and can withstand the I pressure load at the same time. |

9 | Plate | The element for heat transfer, providing the medium flow path and heat exchange surface. |

10 | Gasket | Prevents the mixing or leakage of media and distributes them among different plates. |

11 | Intermediate Partition | By installing intermediate partitions at different positions between the fixed plate and the movable plate, a single device can handle multiple media simultaneously and perform multi-stage operations. |

SIPING ViEX HEAT EXCHANGE EQUIPMENT CO.,LTD.

SIPING ViEX HEAT EXCHANGE EQUIPMENT CO.,LTD.