Shell and tube heat exchanger in accordance with ASME and GB150 | GB151 standards

It has high temperature and high pressure resistance, mature maintenance technology, wide range of material selection and wide application conditions.

Enhanced heat transfer

Arc tube, corrugated tube, spiral tube, plasma tube, three-dimensional rib tube, baffle tube, spiral baffle plate.

Shell and tube heat exchanger is also called tubular heat exchanger. It is an inter wall heat exchanger with the wall of the tube bundle enclosed in the shell as the heat transfer surface. This kind of heat exchanger is simple in structure and reliable in operation. It can be made of various structural materials (mainly metal materials). It can be used under high temperature and high pressure. It is the most widely used type at present. Shell and tube heat exchanger is an important equipment in the process of oil refining, chemical industry, electric power and other industries. According to statistics, the equipment accounts for about 40% of all static equipment in the refinery. It is not only the main equipment in the process flow, but also the main means for enterprises to reduce energy consumption and cost. Therefore, the technical level of shell and tube heat exchanger is one of the main marks of the advanced degree of the refinery.

As the leading manufacturer of heat exchange equipment industry in China, Vickers is also the manufacturing base of shell and tube heat exchanger. The company holds the design license and manufacturing license of special equipment (pressure vessel D1, D2) of the people's Republic of China, and has more than 100 kinds of shell and tube heat exchanger series products, which are suitable for the professional needs of different fields and industries. The whole process of product design, manufacturing, inspection and service conforms to the requirements of ISO9001 international quality system, pressure vessel (GB 150.1 ~ gb151.4-1998), heat exchanger (GB / t151-2014) and safety technology supervision regulation for stationary pressure vessel (tsg21-2016).

Shell and tube heat exchanger is one of the leading products of our company. It has many unique features in the structural design, product manufacturing and application technology of heat exchanger. In addition to the conventional design and manufacturing technology of shell and tube heat exchanger, it is mainly committed to the development and processing of high-efficiency shell and tube heat exchanger with enhanced heat transfer elements, and has major technical innovation in the field of heat transfer enhancement, which makes Vickers tube Shell heat exchanger has the characteristics of high efficiency and stability. Compared with the ordinary smooth tube heat exchanger, the heat transfer efficiency is significantly improved, the resistance loss is reduced, and the optimal matching of heat transfer efficiency and resistance drop is realized. Among them, the shell and tube heat exchangers such as bellows type, screw tube type, baffle rod type and spiral baffle plate type are the main products of our company, and their performance and quality are at the international advanced level. The products have been widely used in petrochemical, oil refining, light industry, electric power, metallurgy, water conservancy and other industries.

Product classification

1. Fixed tubesheet: the tubesheets at both ends of the tube bundle are connected with the shell as a whole, and the structure is simple, but it is only suitable for heat exchange operation when the temperature difference of hot and cold fluid is small and the shell side does not need mechanical cleaning. When the temperature difference is slightly larger and the shell side pressure is not too high, an elastic compensation ring can be installed on the shell to reduce the thermal stress.

2. U-tube type: each heat exchange tube is bent into a U-shape, and its two ends are respectively fixed in the upper and lower zones of the same tubesheet. With the help of the baffle in the tube box, it is divided into inlet and outlet chambers. The structure of the heat exchanger is simpler than that of the floating head type, but the tube side is not easy to clean.

3. Floating head type: the tube plate at one end of the tube bundle can float freely, completely eliminating the thermal stress; and the whole tube bundle can be drawn out from the shell, which is convenient for mechanical cleaning and maintenance. Floating head heat exchanger is widely used, but its structure is complex and its cost is high.

4. Stuffing box type: the shell and tube heat exchanger is fixed between one end of tube bundle and tube plate, and the other end is sealed by external packing box. Due to the free expansion and contraction of the tube bundle, there is no thermal stress between the tube bundle and the shell. The utility model has the advantages of simple structure, convenient manufacture, easy maintenance and cleaning. The disadvantage is that the shell side fluid may leak out, so the pressure and temperature are limited. It is not suitable to use volatile, flammable, explosive and toxic media in shell side.

Product composition

Shell and tube heat exchanger is composed of tube box, shell and tube bundle. Tube bundle is the core of shell and tube heat exchanger, in which the heat exchange tube as a heat conducting element determines the thermal performance of the heat exchanger. Another basic element which has great influence on the thermal performance of heat exchanger is baffle (or baffle rod). The tube box and shell mainly determine the pressure bearing capacity and operation safety and reliability of shell and tube heat exchanger.

working principle

Shell and tube heat exchanger is a kind of wall heat exchanger. The fluid channel formed in the heat exchange tube is called the tube side, and the fluid channel outside the heat exchange tube is called the shell side. When the tube side and shell side pass through two different temperature fluids, the higher temperature fluid transfers heat to the lower temperature fluid through the heat exchange tube wall. The higher temperature fluid is cooled and the lower temperature fluid is heated, thus realizing the purpose of two fluid heat exchange process.

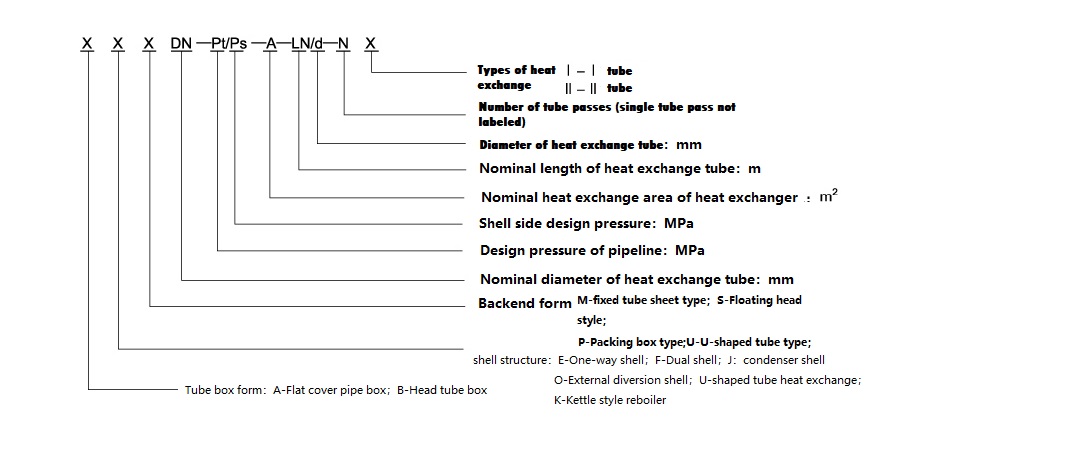

Model representation

Three necessary conditions for inspection of pressure vessels under the supervision of the code

1. The maximum working pressure is greater than or equal to 0.1MPa (excluding the static pressure of liquid column);

2. The inner diameter (non-circular section refers to its maximum size) is greater than or equal to 0.15 meters, and the volume is greater than or equal to 0.025 cubic meters;

3. The medium is gas, liquefied gas or liquid with the highest working temperature higher than or equal to the standard boiling point.

SIPING ViEX HEAT EXCHANGE EQUIPMENT CO.,LTD.

SIPING ViEX HEAT EXCHANGE EQUIPMENT CO.,LTD.